Therefore, it is important that their strength be adequately tested and procedures be put in place to standardize the testing process. Researchers working with The Steel Network have devised a series of calculations that accurately provides the strength of steel framing connections prior to and after the application of additional strength limiting factors.

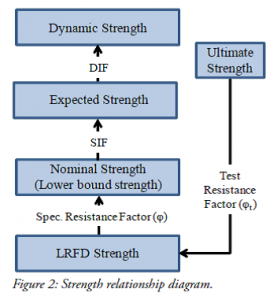

These calculations, published in the July 2012 issue of Structures Magazine, illustrate the relationship between a connection’s ultimate, LRFD, Nominal, Expected and Dynamic strengths. Each of the strengths has its own important definition.

Ultimate strength is the total strength of the component without any limiting or reducing factors. In other words, it is the theoretical maximum strength of the component. Load and Resistance Factor Design (LRFD) strength is derived from the ultimate strength multiplied by the initial Test Resistance Factors. Nominal Strength is then obtained by multiplying the LRFD strength by the equation for the strength resistance factor. Expected Strength requires the static increase factor be applied, and the Dynamic Strength requires that the Dynamic Increase factor be applied.